Do you know what a circuit breaker anti-pumping relay is? How does it work? Or why is it used with a circuit breaker? Well, in this blog post, we will try to find out the answers of all of our queries for anti-pumping.

A circuit breaker is a very important equipment for a high-voltage power system. It protects the system from high current or voltage during a faulty condition. On the other hand, an anti-pumping relay or an anti-pumping device protects the circuit breaker from maloperation, especially prevent repeated closing. It prevents the breaker from closing under faulty conditions.

What is Anti-Pumping Relay?

If I explain anti-pumping within a sentence, then I say – Anti-pumping relay permits only one close operation for the circuit breaker to give a continuous pulse. That means, you press the circuit breaker closing pulse and hold on, at that time the fault persists in the system and the breaker tripped again. Though you are pressing the closing pulse continuously, the breaker will not close again. This is the main function of the anti-pumping relay.

Why is the Anti-Pumping Relay Used?

An anti-pumping relay is used as an interlock in breaker closing circuits. It avoids repeated closing and tripping during fault conditions.

Suppose a persistent fault occurred on your system, and you pressed the closing switch before clearing and held on. If your breaker lacks an anti-pumping relay, it will close and trip repeatedly. As a result, the system equipment will be damaged due to abnormal voltage and current. Also, there is a possibility of burning the breaker trip coil and close coil. But if the anti-pumping relay works properly, this will never happen.

Now, a question will arise: why does anyone press the closing switch and hold on? Well, a person can do this very unlikely. But what will you do when your relay close contact gets sorted! This incident may occur in any relay.

That’s why! The anti-pumping device is used all over the world.

Anti-Pumping Relay Working Principle

In this section, we will find out the answer to the question of how an anti-pumping relay works.

An anti-pumping relay uses a coil and a normally closed contact. When a closing pulse is given to the breaker, the breaker will close and energize the anti-pumping coil. When the anti-pumping coil gets energized, its normally closed contact will open. And disconnect the closing coil from the closing switch.

If the fault persists, then the breaker will trip and never close until you release the closing switch. When you release the closing switch, the anti-pumping coil will be de-energized, and again the normally closed contact will close. So, the closing coil will get a pulse from the closing knob. As a result, this time breaker will close this time.

Circuit Diagram of Anti-Pumping Relay

Let’s discuss anti-pumping with a circuit diagram.

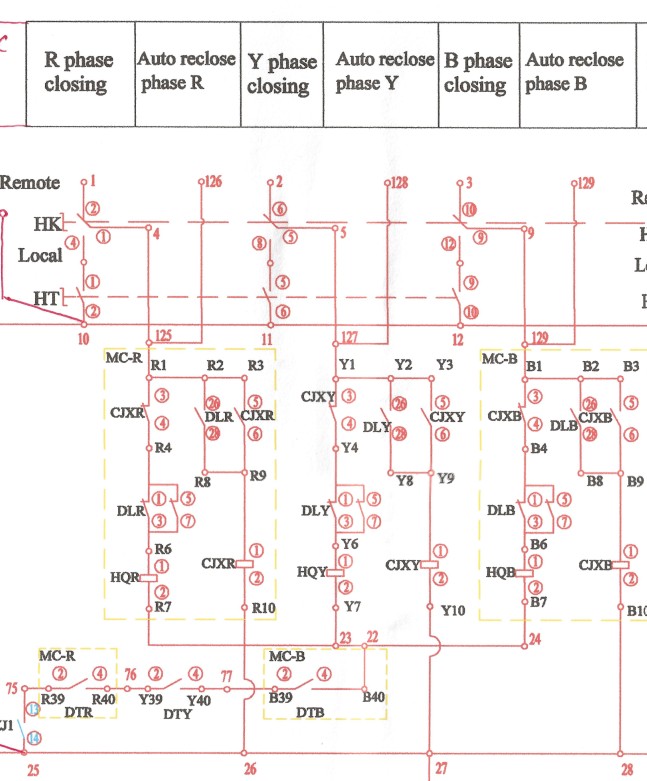

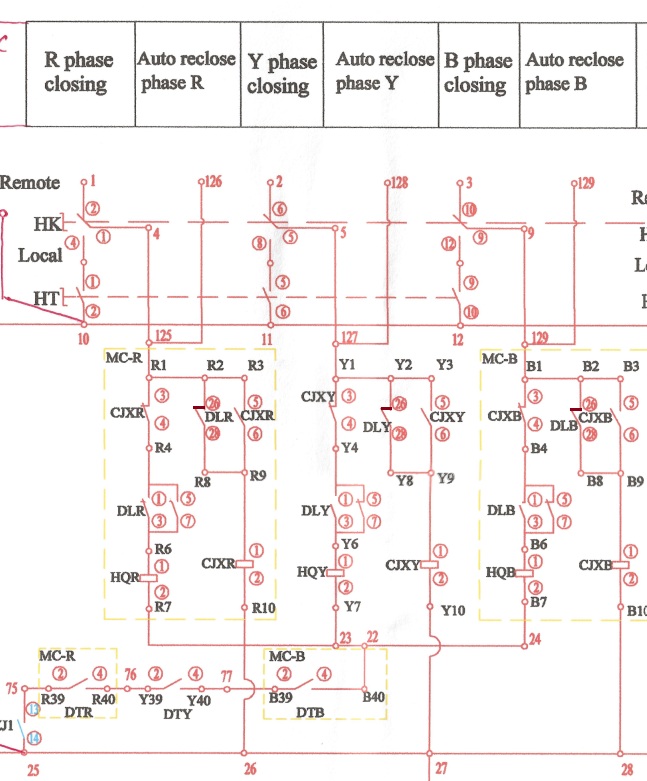

This is a circuit diagram of the closing coil of a three-phase breaker, which includes an anti-pumping relay.

Now, understand the mechanism. Here, the CJXR(R used for phase R) between terminals 1 and 2 is an anti-pumping coil. CJXR contact between terminals 3 and 4 is a normally closed(NC=normally closed) anti-pumping contact. When the CJXR coil deenergized, the CJXR contact made. On the other hand, when the CJXR coil is energized, the CJXR contact will open.

CJXR contact between terminals 5 and 6 is a normally open(NO=normally open) anti-pumping contact. When the CJXR coil deenergizes, this contact opens, and when the CJXR coil is energized, this contact will open.

DLR contacts are related to the breaker status. When the breaker is open(which is shown in the above figure), the normally closed DLR contacts between terminals 1,3 and 5,7 are closed, and the normally open DLR contact between terminals 26, 28 is opened. If the breaker is closed(shown in the figure below), then the normally closed DLR contacts between terminals 1,3, and 5,7 are opened, and the normally open DLR contact between terminals 26, 28 is closed.

HQR is the closing coil, HK is the local/remote selector switch, and HT is the opening & closing switch. DTR, DTY, and DTB are auxiliary switches for the circuit breaker spring charge status for R, Y, and B phases, respectively. They make contact when the spring charge is okay.

When we press the closing switch HT, the breaker closing coil gets positive voltage through CJXR NC and DLR NC. As anti-pumping is not energized yet, CJXR NC is close. Also, DLR NC is closed as the breaker is not closed yet.

The closing coil gets negative through DTR, DTY, and DTB contacts; if the spring charge is okay.

When the breaker closing coil gets both positive and negative voltage, the breaker will close. As the breaker is closed, the DLR normally open contact will close, and the CJXR anti-pumping coil gets energized. So, the CJXR normally closed contact will open, and the CJXR normally open contact will close. Suppose you are holding the closing switch, and the breaker trips due to a fault. Now the breaker will not close again, though you are holding the closing switch. Because the anti-pumping coil CJXR is energized through the closing pulse and the R3 and R9 path. As the CJXR coil energizes, the normally closed CJXR contact will open. This disconnects the closing coil from the positive voltage. The breaker will not close until you release the closing switch.

Once you release the closing switch, the CJXR coil deenergizes, and then the breaker will be ready to close.

Here, I have discussed only for a single phase. This mechanism is the same for all phases.

Advantages of Anti-Pumping Relay

Protection of the Circuit Breaker Mechanism

The anti-pumping relay safeguards the circuit breaker’s closing and tripping mechanism by blocking repeated operations. Without this protection, continuous closing commands during a fault could cause severe mechanical stress. This leads to damage or even permanent failure of the breaker.

Increased Safety and Reliability

By ensuring that the breaker closes only once for a single command, the anti-pumping relay reduces the risk of accidents, equipment failure, and power instability. This increases the overall reliability of the power system and enhances operator safety.

Prevents Unnecessary Mechanical Wear

Repeated closing and tripping cycles put extra strain on the breaker’s moving parts. The anti-pumping relay prevents such unnecessary operations, extending the lifespan of the circuit breaker and reducing maintenance costs.

Improves System Stability

During fault conditions, continuous breaker operations can cause system disturbances and voltage fluctuations. The anti-pumping relay eliminates this issue, ensuring smoother system recovery and a stable power supply.

Common Issues of Anti-Pumping Relay

Relay Failure or Wiring Issues

One of the most common problems with anti-pumping relays is faulty wiring or internal relay failure. If the wiring is loose, shorted, or incorrectly connected, the relay may not operate as intended. This can result in either the breaker failing to close or closing repeatedly without restriction. Regular inspection of the control wiring and relay contacts helps prevent such issues.

Breaker Not Closing Due to Faulty Anti-Pumping Relay

A defective anti-pumping relay can sometimes block the breaker from closing, even under normal conditions. In such cases, operators may mistakenly assume the breaker mechanism is faulty, while the actual issue lies in the anti-pumping relay or its auxiliary contacts. Testing the relay and verifying its operation during scheduled maintenance can quickly identify and resolve this problem.

The anti-pumping relay is a small but vital component in circuit breaker control circuits. It ensures that a breaker does not close repeatedly under faulty or continuous closing commands, thereby protecting the breaker mechanism and the overall power system.

By preventing repeated operations, the anti-pumping relay enhances system safety and improves operational reliability. This extends the mechanical lifespan of circuit breakers. So, must check it before the substation commissioning.

Thanks for your reading. I will try to integrate a video on the anti-pumping relay soon. So visit powersynchro regularly.

Pingback: Substation Commissioning Checklist: Step-by-Step Guide

Pingback: How Pole Discrepancy Protection Works in a Circuit Breaker? Power Synchro

Pingback: Transformer Vector Group: Meaning, Types and Phase Shift

Pingback: Operational Interlock of Circuit Breaker, Isolator, and Earth Switch